Transformer-secondary Combination

The combination of transformers, secondary circuit or main, and

the consumers’ services makes up the secondary system. Secondary

systems are predominantly single-phase, except for larger commercial

and industrial consumers, who are supplied from three-phase systems.

While the discussion will be limited to single-phase systems, the principles

and methods employed in their design will serve for other types

of secondary systems.

The number of consumers’ services and their loads, the voltage

drop, the size of conductors, and the spacing and size of transformers

are all variables that are interdependent. They are factors which must

be considered in combination to arrive at a satisfactory design. There

are many theoretical combinations of these factors that will achieve economical

solutions to the problems of design.

For practical purposes, however, these combinations can be reduced

to fewer and more manageable numbers. Certain assumptions

can be made safely:

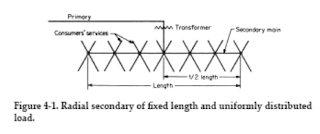

1. The load can be considered uniformly distributed along a secondary

whose length can be considered fixed. Although not strictly

true, this assumption does represent a majority of conditions, but

concentrated or scattered loads must be considered separately.

2. The length of secondary circuit is fixed either by geography or by

the type of design; e.g., each city block could be fed by one or more

secondary circuits. Refer to Figure 4-1.

3. In practice, the number and sizes of conductors and transformers

are limited, usually to two or three in number, and to certain standard

sizes because of manufacturing, purchasing, stocking, and

construction economies.

The problem then is to determine the proper combination of conductor

or wire, transformer, and transformer spacing for the least annual

cost, using the materials available while providing for satisfactory voltage

variations, including flicker. Also, the design should consider not

only present loads, but the economics of supplying future loads as well.

Computers permit study of a greater number of combinations.

Conductor Size

It may be well to begin with a determination of the size of conductor.

The maximum demand for each of the consumers is known and a

coincidence or diversity factor, determined by analyses or from previous

experience, applied. Assuming uniformly distributed loads, the loading

on each half of the circuit (each direction from the transformer) can

be expressed as load density in kilowatts per thousand feet or similar

units.

Voltage Drop

For determining voltage drop, the load can be assumed to be concentrated

at the midpoint of the secondary main between the transformer

and the last consumer, i.e., one-quarter of the length of the conductor

from the transformer. The total load connected to one-half the circuit is

converted into a coincident maximum demand in amperes.

A maximum tolerable voltage drop (to the last consumer) is assumed

and divided by the coincident demand in half the circuit,

expressed in amperes. The result will give the maximum permissible

resistance of the conductor. On the basis of its length (one-quarter of the

circuit), the resistance per unit (1000 ft) can be determined. The standard-

size conductor whose unit resistance is equal to or less than that

calculated can be selected.

This assumes the loads are at or near unity power factor; where

this is not so, impedance values based on the spacing between conductors

must be used. Also, the drop in one conductor is calculated,

which assumes no current in the neutral conductor and a load balanced

equally between the two energized or line conductors; where this is not

so, voltage drop in the neutral conductor must also be calculated and

the greater of the drops in the two line conductors used in selecting the

standard-size conductor.

Losses

The next step is to determine the loss in the secondary mains. The

value of current and the unit resistance of the conductor are known; for

the purposes of determining losses, the full load can be considered to be

at one-third the distance from the transformer. This approximate value

in watts or kilowatts is multiplied by an estimate of the “equivalent

hours” duration to obtain the energy losses in watt-hours or kilowatthours.

This should be multiplied by 4 for the entire length of the two

conductors (neglecting the neutral).

It should be noted that while load curves for a particular period

(day, month, year) vary with the value of current, corresponding curves

for losses vary with the square of the current, even though the curves

may have a similar configuration.

Like the load factor, a loss factor is

the ratio of average power loss for a certain period of time (day, month,

year) to the maximum loss or loss at peak load (for a stipulated time:

15, 30, or 60 min) during the same period. This value can be determined

with sufficient accuracy by analysis of a few typical daily load curves

for the period involved. This loss factor always lies between the load

factor (for long, sustained peak loads) and the square of the load factor

(for short, sharp peaks). The loss factor multiplied by 24 equals the daily

equivalent hours.

Returning to the energy losses, in watt-hours or kilowatt-hours,

these are evaluated at the system cost per kilowatt-hour (which includes

not only fuel costs, but carrying charges on equipment, operating costs,

and other overheads). This value is compared with the carrying charges

(including maintenance costs and appropriate overheads) on the installed

cost of the conductors. If the two values are reasonably close, the conductor

selected is economically satisfactory, according to Kelvin’s law.

Kelvin’s Law

Kelvin’s law is generally expressed as follows: The most economical

size of conductor is that for which the annual charge on the investment

is equal to the annual cost of energy loss.

If these two values are not reasonably close, another size of conductor

may be chosen, or the length of the secondary main (and its

connected loads and its coincident maximum demand) may be changed;

and either process may be repeated until the values of annual charges

and annual cost of energy losses are reasonably close.

Transformer Size

Having determined the tentative size of conductor, the next step is

to determine the size of the transformer to be installed. The value of the

diversified coincident demand for the loads connected to the secondary

main having been determined, the nearest standard-size transformer (in

kVA) to the demand (in kW) is tentatively selected. To allow for future

growth and not to prejudice the life of the transformer, the size chosen

is usually larger than the demand.

The most economical load of a transformer is that for which the annual

cost of its copper loss is equal to the annual carrying charges of the

transformer installed plus the annual cost of the core loss. The core loss

can be considered constant regardless of the load carried by the transformer.

Values of core loss and transformer resistance, both expressed as

percentages at full load, vary with the manufacturer, vintage, size, and

other characteristics, and are found in the transformer specifications;

core loss is usually a fraction of one percent, while resistance is usually

less than 2 percent (reflecting the high efficiency of transformers). Here,

too, if the two values are not close, another size of transformer may be

chosen, or the secondary circuit may be changed so that two or more

transformers supply the load. It may be necessary to review the conductor

size and loads for the new resulting circuits.

It is obvious that any secondary-transformer configuration represents

a compromise. Much depends on the relative costs of material

and labor, which may vary widely from time to time and from place to

place. Further, other considerations may play a great part in the final

determination; e.g., conductor sizes may change to meet mechanical

requirements.

Future Growth

To provide for future growth, loads are adjusted upward by a percentage

estimated to represent probable increase over a specified period

of time. Facilities to serve these increased loads are designed in the same

manner described. The difference in investment costs for each design is

evaluated in terms of the future worth of the present increment of cost

of the additional facilities provided for growth. This is compared to the

cost of installing the facilities at the future time. If it is less, it is desirable

to provide for the future load at the time of initial installation. If not,

provision for future load growth should be dropped, or scaled down to

values and timing that will justify some value of additional cost.

To accommodate the load growth, the transformer and conductors

can be replaced with larger ones, or more popularly, the secondary circuit

can be divided into two or more parts without changing conductors;

a suitably sized transformer is then added to the newly formed secondary

circuits. Comparison of costs and annual carrying charges dictate the

method selected.

Networks

The analysis described pertains to radial secondary circuits. Where

networks are involved, the same principles and methods can be applied

by assuming the network to be divided into a number of adjacent radialtype

circuits, as shown in Figure 4-2; no appreciable error is introduced.

The general principles and methods applied to overhead singlephase

radial-type secondary circuits may be applied to underground

circuits and three-phase three- or four-wire circuits by proper adjustment

of terms to fit the cases. With underground circuits, the lesser current-

carrying capacity of a size of conductor, without overheating, must

be taken into account. In network design, the ability to burn clear the

conductors in the cable under fault or short-circuit conditions should

also be ascertained. These additional considerations may be taken into

account after the economic studies are made.

Rural Systems

Where consumers are scattered, such as in rural areas on in the

case of three-phase consumers in an area supplied essentially at single

phase, the load may be served either by extending the secondary from

one transformer or bank of transformers, or by installing a separate

transformer or transformers to serve those consumers. Annual carrying

charges, including costs of losses, should be compared in selecting the

method of supply.

There are many other problems in the design of secondary systems,

but they lend themselves to the application of the same basic principles

and methods, with proper consideration given to their particular requirements.